Introduction:

This bulletin provides some background on cladding systems and clarifies the intent of the code insofar as systems that are tested for use in non-combustible construction and possibly used in the context of combustible construction – such as conventional wood frame.

The intent of the National Building Code is to limit the use and contribution of combustible cladding systems in non-combustible construction. There are a number of mechanisms to achieve this. Use of the same materials in combustible construction is permitted and applications will be clarified in this Bulletin.

Use of Non-Combustible Cladding

Use of materials that are classified as non-combustible- such as pre-formed steel panels and many reinforced cement-based tiles- do not contribute significant fuel to a fire if supported by non-combustible construction. With current energy performance requirements foamed plastic or other insulation may be introduced to reduce heat losses through the wall assembly. This will invoke other code requirements

The contribution of foamed plastics that may be used to insulate wall assemblies is less significant in the context of combustible construction whereas in non-combustible construction, the contribution of fuel can have a significant impact on the expected performance of walls, ceilings/attic spaces and roofs. Consequently, the code requirements are more onerous in the context of non-combustible construction.

Where thermal protection is required for foamed plastic in wood frame exterior wall assemblies this bulletin will clarify the intent of the code for cladding systems.

Composite Materials

Where a composite material is utilised for cladding purposes, the combustibility can increase due to the contribution of insultation in a ‘sandwich-panel’ construction; in this case each element has to be assessed for combustibility. Even where mineral insulation is used in sandwich -type construction it is hard for these composites to meet the code criteria under 3.1.5.1. In most instances the referenced tests will marginally exceed the criteria to be considered non-combustible which means that technically, the cladding material has to be treated as a combustible material- under 3.1.5.5 of the Code.

It should be noted that fire retardant treated wood has a significantly higher heat release rate- 40-50 MJ/m2- than the criteria set out in 3.1.5.1 and significantly higher than most mineral insulated composite aluminum panels (typically around 10MJ/.m2 if non-combustible core). Also, the flame spread of many S-134 tested panels is zero in comparison with FRTW which has a flame spread of 25.

Use of Combustible Cladding in Non-Combustible Construction

Owing to the vertical configuration of cladding systems, higher than expected vertical flame spread can occur than would be expected if the same material were installed in the horizontal position. External Insulation finish system (known as EIFS) is a lightweight synthetic wall cladding that includes foam plastic insulation and thin synthetic coatings. The cladding requirements of the code therefore reflect criteria originally developed for testing of EIFS systems- now set out in the CAN/ULC S-134 test. Although the test criteria for this and other tests such as the NFPA 285 test differ significantly, these tests are intended to be indicative of large scale fire behaviour- and are not that easy to pass without some input from a fire testing specialist. The NFPA test is considered easier to pass than the S-134 test in Canada. Significantly different results can emerge due to the location of the test facility and the weather on the day of the test. The cost of the CAM/ULC S-134 test is somewhat prohibitive and a failure the first time around can quickly escalate costs out of control.

Figure 1: NFPA 285 test in progress.

Figure 2: Images from a recent CAN/ULC S-134 test of architectural cladding system.

Combustible Cladding Options Under the Code

3.1.5.5 of the Code is not entirely clear and a rational explanation of how it should be applied is difficult once different sections and their intent are applied in the context of spatial separation as well as other issues including thermal protection of foamed plastics. That said this bulletin summarises what applies in the vast majority of cases.

Under 3.1.5.5. (1) the use of combustible cladding on unsprinklered non-combustible buildings is limited to 3 storeys- the typical walk up apartment building for instance. Where sprinklered, the use is restricted to:

Assemblies where any foamed plastics are protected by a thermal barrier- on the inside of the building.

Wall assemblies that pass the criteria of 3.1.5.5 (3) and (4) when tested in conformance with the CAN/ULC S-134 “Fire Test of Exterior Wall Assemblies. These sentences are essentially the pass criteria of the S-134 test. It should be noted that the S-134 test does not test assemblies in combustible construction such as wood frame. What this means is that where combustible construction is permissible, it is acceptable to use an S-134 system on the outside of the assembly as it does not significantly reduce the cladding performance if the S-134 pass criteria have been satisfied. The system has to include the complete assembly including the 5/8inch exterior GWB.

Based on sentence 3.1.5.5.(1), fire retardant treated wood would not satisfy the pass criteria of sentence (3) and (4) as heat release of FRTW is too high. Sentence (5) however, essentially permits it despite the restriction under the above pass criteria. Also, 3.2.2.50 of the BC Building Code 2012 for 5 and 6 storey sprinklered buildings, permits both FRTW or an assembly that satisfies the CAN/ULC S-134 criteria and has a thermal barrier on the inside.

Based on the code wording FRTW would be permitted without a thermal barrier unless the assembly incorporates foamed plastic requiring thermal protection.

An assembly tested to the CAN/ULC S-134 would require both a thermal barrier on the inside as well as the external GWB typically incorporated as part of the test assembly. This would be standard practice in wood frame applications where there is often foamed plastic in the wall cavity. However, if used in non-combustible applications without foamed plastic insulation then this would seem to be unjustified.

Going back to the requirements pertaining to combustible cladding in non-combustible construction there is an exception under 3.1.5.5.(2): where table 3.2.3.7 requires non-combustible cladding.

However, there are various exceptions to the requirement for non-combustible cladding and the main restriction is where the permissible openings are less than 10%. In this case cladding must be non-combustible. As such an S-134 tested system would not be acceptable. This is clarified in the Appendix A of Division B Part 3.

Where the openings permitted are at least 10% then 3.2.3.7 (3) defers back to the S-134 pass criteria set out in 3.2.5.5 which we just reviewed.

Where openings are more than 25% and less than 50% FRTW can be used under certain conditions provided the limiting distance is at least 5m and cladding meets the Part 9 requirements. Also, there is also a general cross reference in 3.2.3.7.(5) back to 3.1.5.5 provided the permissible openings are more than 10% and not more than 25%.

Given the ways these sections are laid out it is not surprising that there is confusion over how different requirements are intended to apply.

Foamed Plastic in the Exterior Building Face

There is a series of requirements under 3.2.3.8 setting out criteria for protection of foamed plastic in the exposing building face; however, assemblies that comply with 3.1.5.5 (S-134 etc. again) do not require to meet the requirements set out in 3.2.3.8 sentences (1) and (2). This is confusing as we have seen that a thermal barrier is specified in the requirements for 6 storey wood frame construction. It appears that the 3.2.2.50 requirements anticipated foamed plastic use and therefore have required it under 3.2.3.8 sentence (3). This also applies under 3.1.5.5 (1) (b)

It should however also be noted that fire blocks are required in exterior walls as per 3.1.11- Fire Blocks in Concealed Spaces. Essentially, this requires fire blocking at each storey and every 20m horizontally unless the insulation is either non-combustible or has a flame spread not more than 25 and has vertical firestopping every 10m vertically. Where there is an air space there should be only one air space and the maximum depth of this should be 25mm (1in.)

Composite Panel Systems

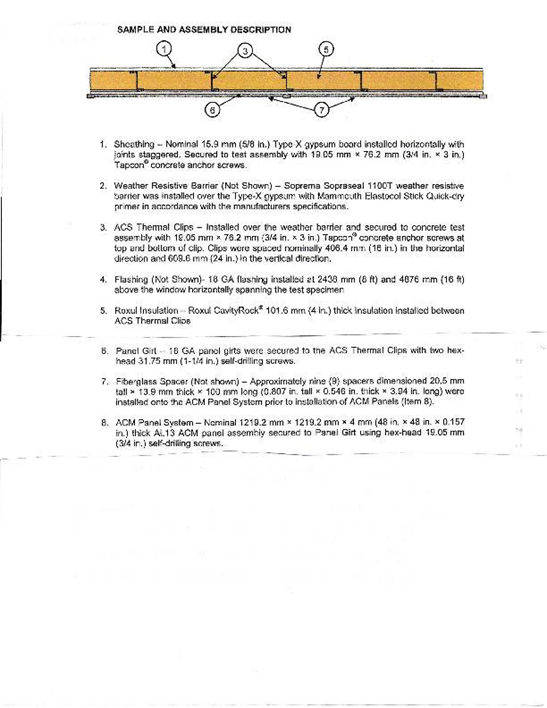

There are several manufacturers that have successfully subjected their systems to the CAN/ULC S-134 test. These systems are designed for use in non-combustible construction but can be used in combustible construction and will not adversely affect the performance of the wall assembly-even if wood frame. The assembly for non-combustible construction consists of:

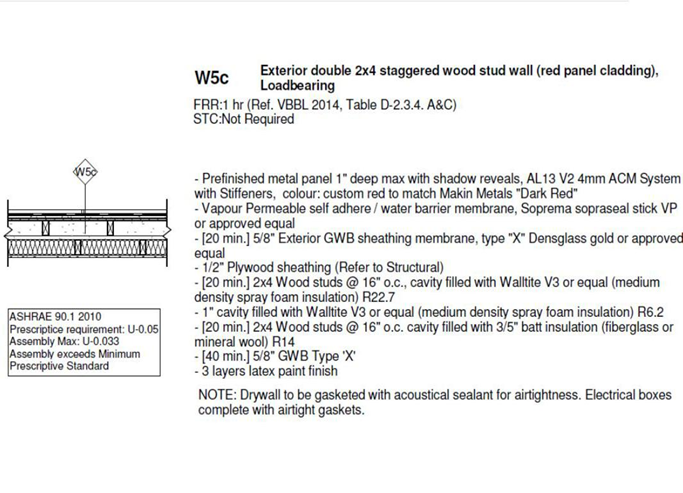

If the wall is of combustible construction then it is common to use double- walled construction with insulated cavity walls for energy conservation. Where the wall requires a rating, this is typically provided by 1 or more layers of gypsum wallboard on the room side.

Where foamed plastic is sprayed in place for insulation and thermal performance of the wall the foamed plastic in combustible construction typically requires a thermal barrier with certain exceptions.

In non-combustible construction the exterior requirements are more complex but generally:

In most circumstances except for unsprinklered buildings over 18m a thermal barrier of 12.7 (0.5 in.) is required.

Adjacent spaces in wall assemblies are exempted.

For unsprinklered buildings over 18m the board has to be taped and filled- partly due to potential smoke spread.

Attics, interior walls and ceiling assemblies in unsprinklered buildings over 18m have thermal protection increased to 15.9mm thermal barriers taped and filled.

Factory- assembled wall units are dealt with separately.

Examples of a Composite Panel/Architectural Cladding System.

Generally composite panel system consists of the following components. The following are based on the AL13 architectural cladding system.

In combustible construction, the assembly is typically used on the outside of a double wood frame typically) assembly as shown below.

Summary:

Materials that meet the requirements of 3.1.5.1 are permissible for use in non-combustible construction.

Composite panels utilising non-combustible insulation are not able to be classified as non-combustible per se and are dealt with in 3.1.5.5 and elsewhere in the Code.

Use of systems classified as combustible for non-combustible construction typically are required to:

Have a thermal barrier: generally, 12.7mm GWB.

Satisfy the CAN/ULC S-134 test criteria unless openings are limited to a maximum of 10% or

Satisfy the requirements of FRTW with the same limitation on openings.

Use of CAN/ULC S134 assemblies in non-combustible construction must be the same as the tested assembly.

Use of the same assembly is permitted in non-combustible construction and these should be the same assembly on the building exterior with a thermal barrier on the inside.

Fire blocking has to be provided as destribed herein.

Prepared By:

John Ivison

Date: July 19th 2018